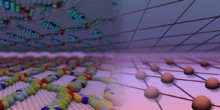

Although they are sometimes viewed as no more than dividing surfaces between neighboring constituents, solid-state interfaces in fact have distinct physical properties of their own. We are using the properties of interfaces to design new materials with radically enhanced performance under extreme irradiation and mechanical loading.

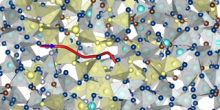

Although they may seem benign, hydrogen (H) and helium (He) can both cause severe embrittlement in structural materials. H embrittlement is especially problematic in acidic environments, such as those encountered in deep oil wells, while He embrittlement may occur in nuclear reactors. By controlling how H and He atoms diffuse, cluster, and interact with crystal defects, we are designing new embrittlement-resistant materials for energy applications.

Crystalline materials are tough, but susceptible to radiation damage. To create materials with significantly improved safety, performance, and reliability for advanced nuclear reactors, we are investigating the radiation response of amorphous (non-crystalline) materials. Combining both crystalline and amorphous solids into composites may lead to materials that capitalize on the strengths of both while compensating for their weaknesses.

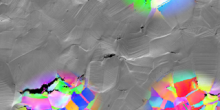

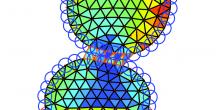

Many materials are so complex, that we can only gain partial understanding of their structures and properties using individual experimental or modeling methods. However, we can gain a more complete picture by combining results from many kinds of different techniques. Bayesian inference provides a rigorous mathematical framework for intelligently combining vastly different types of data such that the whole is greater than the sum of the parts. We are applying this technique to infer the properties of grain boundaries as a function of their crystallographic character.

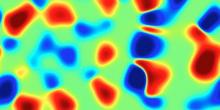

Wear is a life-limiting materials degradation mechanism in many applications. For example, wear by grid-to-rod fretting (GTRF) is the most common cause of fuel leaks in current nuclear reactors. We are developing microscale simulations for modeling wear at the level of single asperities and debris particles. These simulations will lead to better predictions of wear and to the design of materials with improved wear resistance.

Nano-metallic materials—such as nanocrystalline polycrystals, nanolaminates, or nano-porous solids—have superior properties compared to their bulk counterparts. Moreover, their behavior may be tailored for specific needs by controlling microstructure and internal morphology. We are designing new nano-metallic materials by engineering local porosity, interface curvature, and grain boundary networks via a design process that integrates theory, modeling, and experiments.

Nano-metallic materials—such as nanocrystalline polycrystals, nanolaminates, or nano-porous solids—have superior properties compared to their bulk counterparts. Moreover, their behavior may be tailored for specific needs by controlling microstructure and internal morphology. We are designing new nano-metallic materials by engineering local porosity, interface curvature, and grain boundary networks via a design process that integrates theory, modeling, and experiments.

Nano-metallic materials—such as nanocrystalline polycrystals, nanolaminates, or nano-porous solids—have superior properties compared to their bulk counterparts. Moreover, their behavior may be tailored for specific needs by controlling microstructure and internal morphology. We are designing new nano-metallic materials by engineering local porosity, interface curvature, and grain boundary networks via a design process that integrates theory, modeling, and experiments.

Nano-metallic materials—such as nanocrystalline polycrystals, nanolaminates, or nano-porous solids—have superior properties compared to their bulk counterparts. Moreover, their behavior may be tailored for specific needs by controlling microstructure and internal morphology. We are designing new nano-metallic materials by engineering local porosity, interface curvature, and grain boundary networks via a design process that integrates theory, modeling, and experiments.

Nano-metallic materials—such as nanocrystalline polycrystals, nanolaminates, or nano-porous solids—have superior properties compared to their bulk counterparts. Moreover, their behavior may be tailored for specific needs by controlling microstructure and internal morphology. We are designing new nano-metallic materials by engineering local porosity, interface curvature, and grain boundary networks via a design process that integrates theory, modeling, and experiments.

Nano-metallic materials—such as nanocrystalline polycrystals, nanolaminates, or nano-porous solids—have superior properties compared to their bulk counterparts. Moreover, their behavior may be tailored for specific needs by controlling microstructure and internal morphology. We are designing new nano-metallic materials by engineering local porosity, interface curvature, and grain boundary networks via a design process that integrates theory, modeling, and experiments.